Windings¶

Command: pre_models(“Gen_winding”)

Automatic winding scripts are usually used with a parameter-based model.

Example:

m.tot_num_slot = 12.00 -- Total Number of slots

m.num_poles = 4.00 -- Number of Poles 2p

m.num_phases = 3.00 -- Number of Phases m <= 500

m.num_layers = 1.00 -- Number of Layers per slot u

m.num_wires = 100.00 -- Number of wires per slot side

m.current = 20.00 -- Wdg-Current [A] or flux [Vs/mm]

m.coil_span = 3.00 -- Coil span >= 1

m.num_slots = 3.00 -- No of slots in FE-Model (Rot-Mot)

m.mat_type = 1.00 -- Ma-type:1=Rot;21=lin-x;22=lin-y

m.wind_type = 1.00 -- W-typ:1=w&cur;2=w&flux;3=bar&cur

m.win_asym = 1.00 -- asy. slot pitch: 1=sym.; <1=asym.

m.wdg_location = 1.00 -- Wdg location: -1: intern 1: stator; 2: rotor

m.curr_inp = 1.00 -- CURR:Const:0<< Q-axis:1 D-axis:-1

pre_models("Gen_winding")

Command: pre_models(“gen_pocfile”)

Automatic creation of a POC file, which is required for the fast calculation routines run_models (“mult_cal_fast”) (see Multiple Calculation) or run_models (“pm_sym_fast”) (see Simulation PM/Reluctance and DC-excited Synchrounous Machines) and defines the current waveform vs. the rotational position.

Typical structure of the POC file of a 3-phase machine with sinusoidal current (see FEMAG-manual):

POC-File | Comment

-------------+-----------------------------------------------------

3 | No. of phases

1 | Nummer des Wicklungsstranges 1

2 | Nummer des Wicklungsstranges 2

3 | Nummer des Wicklungsstranges 3

30.000000 | Zero-crossing angle of the EMF in phase 1

150.00000 | Zero-crossing angle of the EMF in phase 2

270.00000 | Zero-crossing angle of the EMF in phase 3

180.00000 | Mechanical rotation angle of 1 electrical period

sin | Current waveform type

0.0000000 | Schrägungswinkel (Phase-shift angle?)

0 | Anzahl von Schrägungsstufen (No. of phase-shifts?)

Note

Automatic creation of the POC file for rotating machines is currently possible only in the polar coordinate system (cosys(polar)).

End-winding distribution and end-turn length¶

The following commands can be used to define the approximate shape of the end-winding. This data is used to estimate the end-winding self- and mutual-inductance components for the individual coils. These inductances are combined into the d- and q-axis inductances. (“Eigen-und Gegeninduktivitäts-Anteile des Wickelkopfes”)

The end-winding shape definition is also used to estimate the relative end-winding length. The resulting end-winding length is used to adjust the relative conductor length. When the armature length (arm_length) > 1mm, end-winding length is added to it and related to the armature length.

culength = (arm_length+end_winding_length)/arm_length

If the armature length has not been defined (arm_length = 1mm), the relative end-winding length is related to a fictitious armature length of 100 mm.

culength = (100mm+end_winding_length)/100mm

The relative winding length can be obtained at any time with the command

rl1,rl2 = get_dev_data ( "cond_rel_length" )

and it can be adjusted. (See get_dev_data).

Available end-winding definitions¶

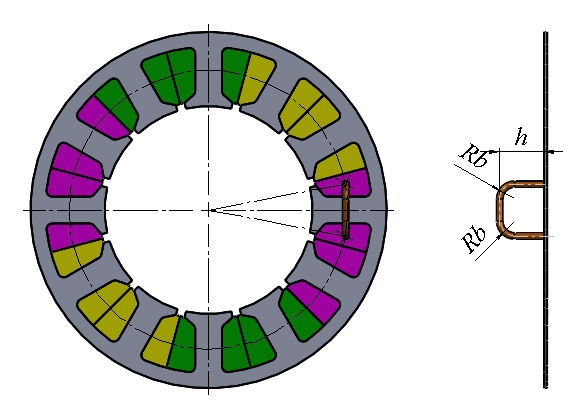

Command: pre_models(“leak_tooth_wind”)

Calculate the leakage inductance of a single-tooth winding.

cCall: leak_tooth_wind

Example for the input:

m.nseg = 2.000 -- Number of segments

m.npolsim = 5.000 -- Number of poles simulated

m.fc_radius = 34.250 -- Radius air-gap center (torque) [mm]

m.arm_length = 100.000 -- Effect. armature length[mm]

m.endheight = 10.000 -- End winding height h[mm]

m.bendrad = 4.000 -- Bending radius Rb[mm]

m.wiredia = 1.000 -- Wire diameter dw[mm]

m.arm_length = 100.000 -- Effect. armature length[mm]

pre_models("leak_tooth_wind")

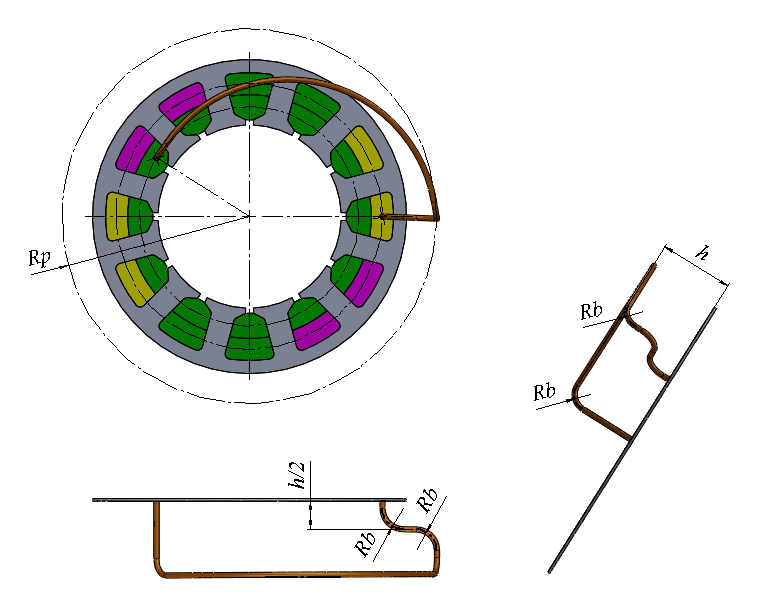

Command: pre_models(“leak_dist_wind”)

Calculate the leakage inductance of a distributed winding.

call: leak_dist_wind

Example for the input:

m.nseg = 2.000 -- Number of segments

m.npolsim = 2.000 -- Number of poles simulated

m.fc_radius = 24.900 -- Radius air-gap center (torque) [mm]

m.arm_length = 100.000 -- Effect. armature length[mm]

m.perimrad = 44.000 -- Radius of perimeter Rp[mm]

m.vbendrad = 4.000 -- Bending radius vertical Rb[mm]

m.endheight = 16.000 -- End winding height h[mm]

m.wiredia = 0.560 -- Wire diameter dw[mm]

pre_models("leak_dist_wind")

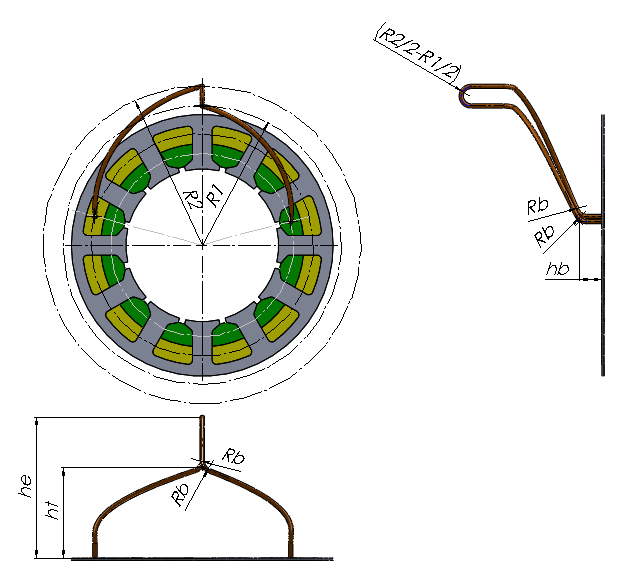

Command: pre_models(“leak_evol_wind”)

Calculate the leakage inductance of an involute winding.

call: leak_evol_wind

Example for the input:

m.nseg = 2.000 -- Number of segments

m.npolsim = 2.000 -- Number of poles simulated

m.fc_radius = 24.500 -- Radius air-gap center (torque) [mm]

m.arm_length = 100.000 -- Effect. armature length[mm]

m.evol1rad = 29.880 -- Top radius of first evolvent R1[mm]

m.evol2rad = 35.856 -- Top radius of second evolvent R2[mm]

m.botlevel = 20.000 -- Level at bottom of evolvents hb[mm]

m.toplevel = 60.000 -- Level at top of evolvents ht[mm]

m.endheight = 80.000 -- End winding height he[mm]

m.evolbend = 2.000 -- Bending radius Rb[mm]

m.wiredia = 1.000 -- Wire diameter dw[mm]

pre_models("leak_evol_wind")